|

HTS

Systems manufactures (6) six different HTS Ultra-Rack models; each

model designed for a different mounting application on the

exterior of the delivery vehicle

or for a specific type of route delivery vehicle.

The HTS-10T Tilt Mount unit is our most popular model

and

is designed for the front of most

vehicles and it has the ability to pivot and tilt outward to clear the

engine hood or cab-over body.

The HTS-30D Direct

Mount unit is designed for the rear of most beverage and battery

side-loader truck bodies. The HTS-20S Swing

Mount

unit is a delivery van application, designed for most commercial

cargo delivery vans.

The HTS-30DTF unit attaches to semi

tractor

frames on large rigs with zero equipment

space, required to drop-hook or must travel bobtail.

The HTS-20S-TD is exclusively

for

Taylor-Dunn electric electric vehicles. The

HTS-30DI Ultra-Rack unit is designed

exclusively for the interior of armored car vehicles,

large

cube vans or box van trucks. Most HTS-10T Tilt Mount applications do

require an HTS adapter plate kit to create a vertical

mounting

surface on front bumpers. Our engineering and fabrication department can

custom design a mounting application for your

vehicles. For

more information about our Hand Truck Sentry System safety and

productivity products, please contact your regional

HTS

Systems distributor, truck body manufacturer, commercial truck leasing

company or your local truck body refurbishing facility.

Image courtesy of LT Verrastro MillerCoors Distributing and Keystone

Truck & Trailer of Old Forge, Pennsylvania - Freightliner M2 - GMC

6500 - International Navistar 4300 DuraStar series.

|

HTS Systems most popular HTS Ultra-Rack model is the HTS-10T Tilt

Mount (front mount) unit, which installs to the front of most truck chassis

models. |

Where

and how a route driver transports a hand truck aboard a vehicle

makes a

huge

impact on worker safety, route productivity and profitability.

Order

the HTS with a customized B&P Liberator hand truck as apart of

your new vehicle options list; incorporating both into

your truck lease plan.

Image of StrongPak Stericycle Navistar DuraStar MaxxForce series with HTS-10T

Ultra-Rack. Ford F350 Super Duty pick-up trucks -

HTS-10T Hand Truck Sentry System securing hand trucks.

Images courtesy of Stadium

International Truck - 2014 Mitsubishi Fuso F180 Canter.

HTS-10T Tilt Mount tilts in seconds to access. B&P

Liberator hand truck locked safely aboard Fuso F180.

Images of Keystone Truck &

Trailer and LT Verrastro MillerCoors Distributor 11-2012

Woodchuck Hard Cider Navistar with VT Hackney side-loader beverage

body and HTS-10T Ultra-Rack.

Image courtesy of

Ryder Truck

- Conklin, New York -

Huff Ice Cream - Sidney, NY. Images courtesy of TransEdge

Truck Centers and Hawk Transport Courier Service

Avoca, Pennsylvania 2009

"An example of

functional engineering at its best!

John Huff - OWNER - Huff ICE Cream - Sidney, New York

"A safe, secure, always accessible solution!

ROBERT HAWK - Hawk Transport Courier

Service LLC. - Dupont, PENNSYLVANIA - HTS Customer 4 years

Hino

Truck 338 series and HTS Ultra-Rack professionally installed by

TransEdge

Truck Center Allentown PA. B&P Manufacturing's Liberator

commercial

hand truck locked securely aboard the HTS-10T Ultra-Rack.

This Hino 338 is equipped with Morgan body and many different accessories for the

driver.

HTS-10T

shown with the new high position adapter plate for low bumpers or trucks

equipped with low

profile tires. This new

Freightliner M2 is equipped

with the Clean Idle

Emissions diesel, recessed front axle for a sharper turning radius and

low profile design for reduced air flow and increased fuel

mileage. This

delivery truck is also equipped with a Johnson Refrigerated Truck Body

and Thermo King freezer unit.

The HTS LED hand truck

release switch is designed for under-dash installations or in-dash

installations. The switch quickly and easily plugs directly into the

fuse port, no cutting or splicing required

The

HTS LED switch prevents the route driver from leaving their hand

truck behind, saves route time, fuel, labor and prevents dangerous

detachment.

When the driver

completes the delivery and returns back to the vehicle there is

no need to re-open the

refrigerated area

to stow the hand truck,

lose temperature,

fuel and time. The driver secures the hand

truck using less

effort and can save a minute or more per stop or 30 minutes per day!

Eliminating

the need to reload the hand truck within the temperature

controlled refrigerated truck body in ambient 75°-80°

degrees weather can save

fleets

$$$

thousands in

reefer fuel!

The final trip back

to the vehicle, before departing can be the most important!

Checking in orders, rotating stock,

signing

bill and check can take up to 15 minutes to complete. This is

ample time for most refrigerated truck bodies to recover

operating temperature.

Then

route driver must reopen the rear cargo door to reload the hand

truck. Opening the door draws the colder air outward and down

and closing

the

door pushes the warmer air up and inward. In warmer climates

this action causes major temperature loss and will normally

cause the reefer units

to

recover cargo temperature and run for approximately 5-8 minutes.

Five minutes X 20 stops = 100 minutes per day or 1.5 gallons of

fuel per truck.

The

HTS Ultra-Rack installed on refrigerated trucks in warmer

climates can save fleets

$6 dollars per day,

$120 per month,

per delivery truck!

Images

courtesy of Richard Mummey - Interstate Battery of Allentown. Route

drivers Rick Smith and Jeff Jones.

Images courtesy of

General Truck Body - Los Angeles, CA. -

Rush Truck Centers

"I

encourage you to take a good look at it. These units save us time and effort

daily. The nice part is the unit comes with a key remote

the RSM can

activate while approaching the vehicle."

RICHARD MUMMEY - Interstate Battery of Allentown

- Walnutport, Pennsylvania - CUSTOMER 4 YEARS - FEBRUARY 2012

Interstate Batteries of Pocono Mountains 335 Peterbilt route

delivery truck w/ HTS-10T. Magliner hand truck locked

securely aboard Interstate Batteries Peterbilt delivery

truck. 02-2013

“Your

hand truck rack is a time saver and a space saver; love it”

Tom GENERY - interstate batteries ROUTE DELIVERY DRIVER - IBS of POCONO

MOUNTAINS - Scranton, Pennsylvania - FEBRUARY 2013

| HTS-30D

Direct Mount unit |

Images courtesy of Durdach Bros. MillerCoors Distributors of Paxinos,

Pennsylvania - HTS customer over 5 years - Mickey Beverage Bodies -

Hessco Truck Bodies - VT Hackney Beverage Body.

| HTS Systems' HTS-30D

Direct Mount (rear mount) Ultra-Rack units designed for most

beverage and battery side-loader delivery truck bodies. |

"The

HTS hand truck rack works great! It's tough enough to survive a

forklift collision! We've ordered more HTS-30D units and rear

camera systems.

Doug Billig - Fleet Supervisor 14 years - Durdach Bros.

MILLerCOORS distributors - PAXINOS, Pennsylvania - customer 5

years - JUNE 2010

Images courtesy of

T. Verrastro Distributors - HTS-30D Direct Mount Ultra-Rack

units - Group Hesse Beverage Body. Images courtesy of

Durdach Bros. MillerCoors - Mickey Beverage Bodies.

"Your

HTS hand truck carrier racks are the best thing out there, when we bought

them; we knew it would take-off around the country!"

Thom Verrastro JR. - T Verrastro Distributing, Incorporated - West Hazelton

Pennsylvania - CUSTOMER 5 YEARS - July 2012

HTS

Ultra-Rack IDEC LED dash release switch with indicator light and alarm.

Navistar chassis and Mickey Beverage Body with Magliner hand truck secured by

HTS-30D Direct Mount Ultra-Rack.

Keystone Light (Coors Brewing)

Freightliner M2 Mickey Beverage Body with HTS-30D Ultra-Rack.

B&P Liberator beverage hand truck locked safely aboard Seagram's

Escapes delivery truck.

Images courtesy of Damian's Ice Cream

and Morgan Corporation. HTS-VDM vertical deck mount bracket for rear landing

platforms.

Häagen-Dazs

Magnum Ice Cream truck with HTS-30D unit.

| HTS-30DTF

Tractor Frame unit |

The HTS-30DTF Ultra-Rack allows food service

fleets to transport hand trucks quickly and safely behind the semi-tractor

chassis.

Freightliner Columbia tractor cab interior -

HTS LED release.

| The new HTS-30DTF Tractor Frame Ultra-Rack

Hand Truck Sentry System is now available for larger commercial semi-tractor

trailer chassis models. |

This new HTS tractor chassis application allows

one or two of our HTS-30D Direct Mount Ultra-Rack units to install on big

rigs, without drilling or welding.

The HTS-30DTF (tractor frame) attaches to the tractor chassis frame

C channel quickly and easily; it can also be removed and

re-installed on new leased fleet equipment.

This tractor chassis design is for both day or sleeper cabs; allows

full tolerance for any turning radius and user standing clearance

between reefer trailers and tractor cab.

Excellent application for delivery companies backhauling sealed

loads, full trailers with zero equipment space and/or semi tractors

that must drop-hook or travel bobtail.

The HTS-30DTF Ultra-Rack allows food

service fleets to transport hand trucks quickly and safely behind the

semi-tractor chassis. B&P Liberator hand trucks locked safely aboard tractor

frame.

Photos courtesy of McLane Distribution Services and Ryder System of New York

- HTS-30DTF-2 units. Freightliner

Cascadia day cab tractor w/ 30DTF-2 Hand Truck Sentry System. 9-2013

McLane Food Service Ryder Volvo with

hand trucks, curb ramp and load lock bars safely aboard. Volvo Ryder

Truck with HTS-30DTF-2 Ultra-Rack unit securing (2) B&P Liberator hand

trucks.

McLane Food Service Ryder Volvo with

hand trucks, curb ramp and load lock bars safely aboard. B&P hand trucks, Magliner

curb ramp and Kinedyne load lock bars secured aboard HTS-30DTF.

Images

courtesy of Interstate Battery of Allentown - Ford E250 heavy duty

cargo van with HTS-20SFE Ultra-Rack.

B&P Liberator battery hand truck locked safely aboard HTS-20SFE

unit.

| HTS-20S

Swing Mount Ultra-Rack designed exclusively for Ford E250 E350 commercial

delivery vans and Sprinter parcel delivery vans. |

In the

commercial van market for companies that deliver parcels, documents, paper

and janitorial products, food vending and medical supplies there are no ideal

methods to safely transport a hand

truck, without tossing

it into the vehicle. Current methods take-up valuable cargo space and

decrease payload storage, damage product and require greater physical effort

to stow the hand truck.

Parcel

drivers constantly handle and shuffle their hand trucks within the van to

gain access and to reach their cargo shelves and packages.

A

standard aluminum

commercial hand truck transported

inside the delivery van will use up

approximately 12' -15' cubic feet of valuable cargo space. When a hand truck

is transported inside a delivery van 5 days a week it translates to a

payload

loss of

240-300 cubic feet per month.

Most parcel drivers move their hand truck out of their way continuously,

actually handling it more than they use it for customer deliveries! It is

dangerous and a DOT

safety violation to

transport a loose hand truck within the cab or cargo area, all equipment must

be secured. The HTS Ultra-Rack is the most advanced hand truck retaining

system for commercial

delivery vehicles in

transit. The HTS-20S Swing Mount unit is designed for the rear of most

delivery vans. The HTS-20S Swing Mount can solve nearly every issue

associated with smaller delivery

vans that transport hand

trucks, saving our customers time, fuel, cargo space and profits! Maximize

your cargo capacity and route productivity, reduce freight damage and prevent

floor corrosion.

The HTS-20S

Swing Mount Ultra-Rack - Hand Truck Sentry System

saves 12'-15' cubic feet of cargo space

every day or 240 -300 cubic feet per month and reduces delivery time and

damages!

| HTS-20SFT

Swing Mount Ultra-Rack unit is designed exclusively for the Ford

Transit Connect mini cargo and parcel delivery vans. |

Ford Transit Connect

commercial min cargo van equipped with HTS Systems'

HTS-20SFT Ultra-Rack holding B&P hand truck. B&P

Liberator hand truck locked safe and secure aboard Transit.

The

HTS-20SFT unit offers numerous advantages for food service

companies looking to reduce operating costs such as; route

delivery time, fuel expenses, injuries,

product

damage and freight claims. Food service companies using

refrigerated vans in warmer southern climates and during the

hot summer months will receive a super

payback

benefit savings! Reducing cargo temperature loss means less

fuel usage, less wear and tear and less maintenance.

Fleets can save $25-$35 dollars of fuel per

week,

per van!

The HTS-20SFT Ultra-Rack application is a smart, safe and

productive method and also looks great on the van! Route

drivers can now stop shuffling and

cross-handling

their hand trucks above and around their cargo to access the

vehicle or products. No more extracting the hand trucks to

the ground to access a single

box,

no wasted route time, reduce labor costs, less physical

effort, also prevent work related injuries. Our Hand Truck

Sentry System models can pay for themselves in

6-8

months and save fleets thousands!

Route delivery time, cargo space, labor costs, freight

claims, vehicle maintenance and equipment loss is Money!

HTS-20SFT maximizes cargo

space in cargo vans, reduces product damage and decreases

delivery time.

HTS-20SFT Ultra-Rack is compatible with most

commercial hand trucks models.

Dodge RAM ProMaster cargo

parcel delivery van with HTS-20SFT Ultra-Rack unit securing

B&P Liberator junior. B&P Manufacturing's B&P

Liberator junior convertible hand truck aboard van.

Ford Transit parcel delivery van equipped with HTS Systems'

cargo van equipment hand truck carrier rack.

HTS-20SFT Ultra-Rack hand truck carrier rack equipped on

Ford Transit mini van.

Images courtesy of Gibbons Ford Dickson City, PA. and

Ford Motor Company - Ford Transit HTS-20SFT Ultra-Rack units swing open beyond 90°

and to 180°

to allow full open door access.

No matter how or

where you store a hand truck inside a cargo van, it takes up

valuable cargo space, damages product, requires physical

effort and can cause work related injuries.

Not Anymore!

HTS-20SFT Swing Mount Ultra-Rack install kit for Transit.

HTS-20SFT allows single door access with out swinging.

HTS-20S saves 12'-15' cubic feet of interior cargo space per route day.

Images courtesy

of UMH University of Missouri Health Care in Columbia, MO. -

Ford Transit Connect mini parcel delivery vans equipped

HTS-20SFT Ford Transit Ultra-Rack units.

11-2014

Ford Transit 250 commercial

parcel cargo delivery van with HTS-20SFT unit. HTS

Systems new trailer hitch receiver unit mounts to any

standard class 3, 2" inch trailer hitch in just minutes.

| HTS-20SF350 Tow Hitch Receiver Swing Mount HTS Ultra-Rack unit is designed food service pick-up trucks with refrigerated truck bodies. |

Images courtesy of South Side Seafood - Ford F350 commercial food truck. HTS-20SF350 Swing Mount Ultra-Rack. B&P Liberator commercial hand truck locked safely aboard F350.

HTS-20SF350 tow hitch receiver swing mount is designed for the rear of commercial pickup trucks using refrigerated truck bodies. Designed for the rear of refrigerated

food service delivery vehicles, this new HTS application saves cargo temperature, route time, valuable cargo space, prevents worker injuries, product damage and

bacterial cross-contamination. The new HTS-20SF350 unit reduces reefer recovery run time, physical effort, thereby saving thousands in fuel and labor costs annually!

The HTS-20S Swing Mount Ultra-Rack

is available for Mercedes, Chrysler and Freightliner Sprinter commercial

delivery vans. The HTS-20S swings outward quickly to access both rear

doors.

| HTS-20S-TD

Swing Mount unit |

Taylor-Dunn

B-248 48V GT electric mail delivery vehicle with

HTS-20S-TD professionally

installed by TMH Toyota

Material Handling of Hayward, California. HTS switch in cab

interior. 07-2011

HTS Systems' HTS-20S-TD Ultra-Rack

equipped on Taylor-Dunn Manufacturing

Company ET-150-74 Electruck. HTS-20S-TD is

compatible with the TD B-248 GT and ET-150-74 chassis models.

HTS-20S-TD Swing Mount Ultra-Racks for

B-248 GT HTS-20S-TD Taylor-Dunn sub mount assembly for

ET-150-74 vehicles.

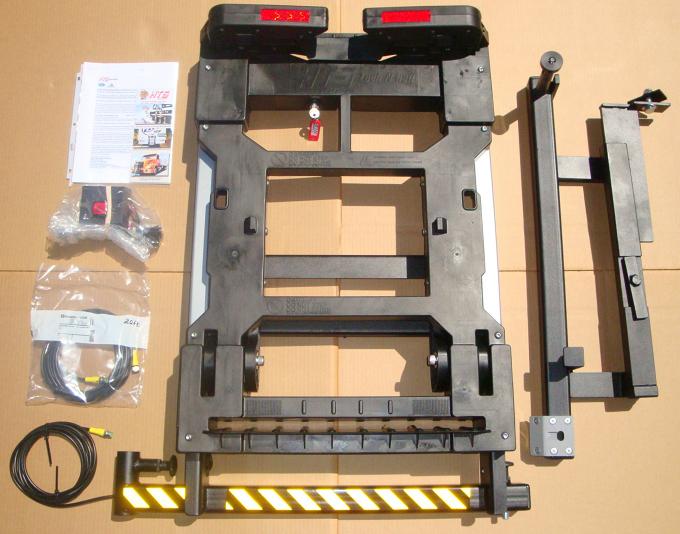

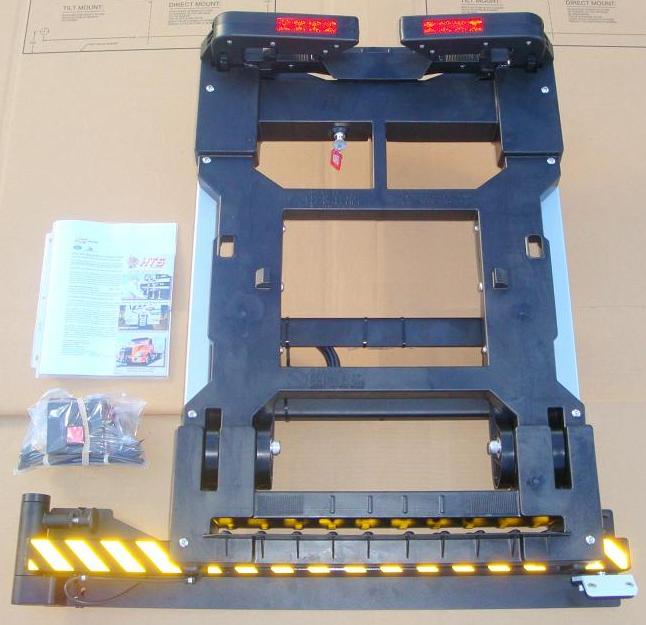

HTS-20S-TD Taylor-Dunn Ultra-Rack unit - complete kit.

| HTS-20S-TD

Swing Mount Ultra-Rack is designed exclusively for Taylor-Dunn B-248 and

ET-150-74 48VDC electric powered delivery vehicles. |

| HTS-30DI

Interior Direct Mount unit |

Mercedes Sprinter van with new

HTS-30DI Interior Mount Ultra-Rack unit.

08-11 B&P Liberator hand truck safely locked for transport.

Activate and unlock hand truck by contacting push rod.

| HTS-30DI Interior Direct Mount Ultra-Rack

designed exclusively for the interior of Armored Car vehicles, Sprinter

vans or tall box van interiors only. |

The new

HTS-30DI Interior Mount Ultra-Rack

installs inside the vehicles cargo area safely secures commercial hand

trucks during travel. Prevent damage to fragile cargo,

interior

damage, broken windows, tripping, falls and worker injuries. Comply with DOT

safety regulations, keeping all material handling equipment secured before

travel.

The

HTS-30DI unit is a vehicle cargo interior

mounting application only and includes a manual release method. It

does not include an electric dash kit or warning system.

HTS-30DI is an excellent application for parcel

freight companies, vending delivery vans, armored trucks, medical supply, food

service routes and professional contractors.

| For

Armored Service Vehicles / Armored Car Delivery Trucks |

We are confident that we

have a safety and ergonomic enhancement that can reduce the amount of times

the vehicle vault is opened by 45% percent! Reduce the vault

access by hundreds of times

per week and also decrease the standard delivery (open-door) time, by hours

per week; thereby increasing the armored personnel safety,

the vault security, the

route productivity; while reducing risk and company liability. We have

observed many guards leaning and reaching with their torso inside the

vehicle.

The guard’s visibility

momentarily obstructed, their back facing towards crowded sidewalks and

parking lots, while focusing on lifting and handling their hand truck. The

hand

truck tires and load plate often transfer dirt, mud and snow into the cargo

area, causing currency bags and valuable items to become wet or dirty. We

have also

been

informed by armored guards who had injured themselves because they slipped on

wet floors within the vehicle and fell onto their hand trucks. The HTS-10T unit

can increase armored personnel safety,

vault security, route productivity, fuel economy and save armored services companies

thousands of dollars

per armored vehicle!

Images

courtesy of Interstate Batteries -

Dallas, Texas - Tom Oliver - Clifford, Pennsylvania and Kenworth

Trucks - Kirkland, Washington 7-2006

Interstate

Batteries 2006 Kenworth T300 - Mickey Body route delivery truck

with HTS Systems' Tilt Mount

(front installations) with Magliner

aluminum hand truck locked safely and securely aboard delivery

vehicle. HTS Ultra-Racks operate

by the dash release switch or the override key.

Image courtesy of

Keystone Paper, PA and Mitsubishi Fuso 5-06 Sterling Truck Corporation - Redford Township MI.

Image courtesy of Canada Dry-Royal Crown Company of Olyphant,

PA.

Easy & Fast

Installation - Rust & Corrosion Resistant - Super Tough & Durable - Hand

Truck Safety Rack

The HTS Ultra-Rack

is designed

to transport the delivery

industry's most popular

commercial hand

trucks and it

can be mounted on nearly any type of

delivery vehicle.

The HTS Ultra-Rack adapter plate makes it possible for

you to

install your

Hand Truck Sentry System

Ultra-Rack unit on almost every

medium and light truck chassis!

Contact your local Penske or Ryder service facility for professional

installation and service on company leased Freightliner and Navistar trucks.

Image courtesy of Pepsi Cola Bottling Group - International

Navistar securing Magliner Junior Gemini convertible hand truck.

Hessco Truck Body with HTS-30D Direct Mount Ultra-Rack.

Pepsi Cola

soda

beverage truck with HTS Ultra-Rack securing Magliner Gemini Jr. convertible hand

truck. The Hand Truck Sentry System is now ready

to receive the hand

truck and prevents the driver from

accidentally leaving the hand truck behind by LED indicator and

the alarm before departure.

Images courtesy of LT

Verrastro MillerCoors Distributing. Locking Magliner hand truck HTS -30D Direct Mount Ultra-Rack.

Images courtesy of Coca Cola - HTS-30D Direct Mount

5-2006

Image

courtesy of Pepsi Cola Bottling Group and International

Navistar.

The

HTS Ultra-Rack has performed over the road in ambient

temperature ranges of -15°F to

101°F for more than 5 years!

This HTS-10T Ultra-Rack Tilt Mount

unit pictured above and below was placed into a

refrigerated environment for deep freeze and ice testing

at -10°F or 23.3°C for 6 days of

adverse weather.

| Winter

Climate Cold

Weather and

Quality Control Testing |

|

|

|

The HTS units are

assembled with 18-8 stainless steel fasteners and super

tough, high impact, glass filled nylon polymers. They will

not rust or corrode like steel brackets or retaining

frames.

For six

continuous days the

HTS Ultra-Rack performed extremely well in dry cold tests and

layered ice

testing! These conditions simulate some

of the

winter

climate conditions found on customer route delivery vehicles.

Operating conditions may vary, depending on severe weather

environments and

sub-zero

temperatures. In

steady Winter climates we recommend cleaning road dirt and grime

by lubricating unit

with silicone spray

and then applying

a

thin layer of silicone grease to HTS Push-Bar rails every 6

months to prevent

sticking.

|

The Hand Truck Sentry System

easily attaches to truck manufacturers curved contoured bumpers.

Navistar with HTS-10T Ultra-Rack.

Sterling 360 cab-over vending delivery truck in Arizona.

|

| HTS-CC

Cone Cradle safety unit |

| HTS-CC

Cone Cradle traffic safety cone deployment system designed for most

straight (box van) trucks and semi van trailers. |

HTS

Systems' HTS-CC Cone Cradle has been met with an incredible amount

of excitement and enthusiasm by fleet professionals, truck body

manufactures and route

delivery

drivers. The HTS-CC is a safer, easier and faster method, requiring

less physical effort, zero climbing, reduce liability and

reduce bacterial cross-contamination.

Whether

it's a road side delivery, parking lot delivery or loading dock

delivery, the new HTS-CC Cone Cradle reduces

accidents, collisions, worker injuries, property

damage,

corporate liability and insurance costs! Using the new HTS

Cone

Cradle with the Three Cone Safety Policy allows route drivers to get

it done safer, faster and

easier,

especially

in

bad weather! The easier it is to accomplish the task, the more

likely drivers will follow safety protocol.

The

driver can quickly-safely deploy three

safety

cones in under 12 seconds. A safe handy asset in bad weather!

Travels safe and prevents bounce out from road potholes, bridge

expansion joints, snow-plow spray

force

and aerodynamic vacuum. The HTS-CC is an all-weather and all-climate

carrier.

The

HTS-CC makes safety cone deployment easier, faster and much safer!

HTS Systems' new HTS-CC Cone Cradle

traffic safety cone deployment system allows route delivery drivers

to access and stow safety cones faster, easier and safer. Deploy

cones in just seconds!

YouTube demo video:

http://youtu.be/iqZfe4Vrn2k

HTS Systems’ new HTS-CC Cone Cradle traffic safety cone deployment

system is world's safest, fastest and easiest!

YouTube demo video:

http://youtu.be/iqZfe4Vrn2k

HTS Systems’ new HTS-CC Cone Cradle traffic safety cone deployment

system is world's safest, fastest and easiest!

HTS-CC

Cone Cradle traffic safety cone deployment system

$ 249.00 each. Distributor and fleet

pricing available, please contact our customer service for more

information.

HTS-CC

Cone Cradle product brochure

Many food service, freight and delivery

companies are implemeting new standard operating procedures (SOP's)

using the HTS-CC

Cone Cradle traffic

safety cone deployment

system, to reduce accidents,

worker injuries, vehicle damage, liability, insurance claims and law

suits. Three Traffic Cone Safety

SOP 6.4.4 Three Traffic

Safety Cones Policy PDF

(Delivery and pick-up safety protocols - for all box trucks

and semi trailer route drivers) courtesy of

JCM Manufacturing.

Available for safety and risk

managers and free to safety teams for download, recopy,

modification or redistribution.

SOP 6.4.4 Three Safety Cone

Policy is public material.

|

|